The Russian lathe is a fascinating piece of machinery that has played a pivotal role in the world of manufacturing and craftsmanship. Whether you're a seasoned engineer, a DIY enthusiast, or simply curious about industrial tools, understanding the intricacies of the Russian lathe can provide valuable insights into its applications and significance. This article delves deep into the history, mechanics, and modern-day relevance of the Russian lathe, offering a comprehensive guide for both beginners and experts.

Originating from Russia, the lathe has been a cornerstone of industrial development for centuries. Its unique design and functionality have made it a preferred choice for various industries, from woodworking to metalworking. The Russian lathe is not just a tool; it's a testament to human ingenuity and the pursuit of precision. In this article, we will explore its evolution, how it works, and why it remains relevant in today's technological landscape.

As we progress, you'll discover the various types of Russian lathes, their applications, and the factors to consider when choosing one. We'll also provide practical tips for maintenance and safety, ensuring you get the most out of your investment. By the end of this article, you'll have a thorough understanding of the Russian lathe and its importance in both historical and modern contexts.

Read also:Is Tyler The Creator A Dad Exploring The Rumors And Facts

Table of Contents

- History of the Russian Lathe

- How the Russian Lathe Works

- Types of Russian Lathes

- Applications in Various Industries

- Maintenance and Safety Tips

- How to Choose the Right Russian Lathe

- Advantages of Using a Russian Lathe

- Modern-Day Relevance of the Russian Lathe

- Technical Specifications and Data

- Conclusion and Call to Action

History of the Russian Lathe

The origins of the Russian lathe can be traced back to the early days of industrialization in Russia. During the 18th and 19th centuries, the country was undergoing significant technological advancements, driven by the need for efficient tools in manufacturing. The lathe, as a fundamental machine tool, was developed to meet the demands of precision engineering.

Russian engineers and craftsmen were instrumental in refining the design of the lathe, incorporating features that enhanced its durability and functionality. Over time, these innovations led to the creation of a distinct type of lathe that became known as the "Russian lathe." Its robust construction and versatility made it a popular choice in various industries, both within Russia and internationally.

Key Innovations in Russian Lathe Design

- Improved spindle mechanisms for greater precision.

- Enhanced bed designs for stability and durability.

- Integration of advanced cutting tools and materials.

These innovations not only set the Russian lathe apart from its counterparts but also laid the foundation for its widespread adoption in industrial settings.

How the Russian Lathe Works

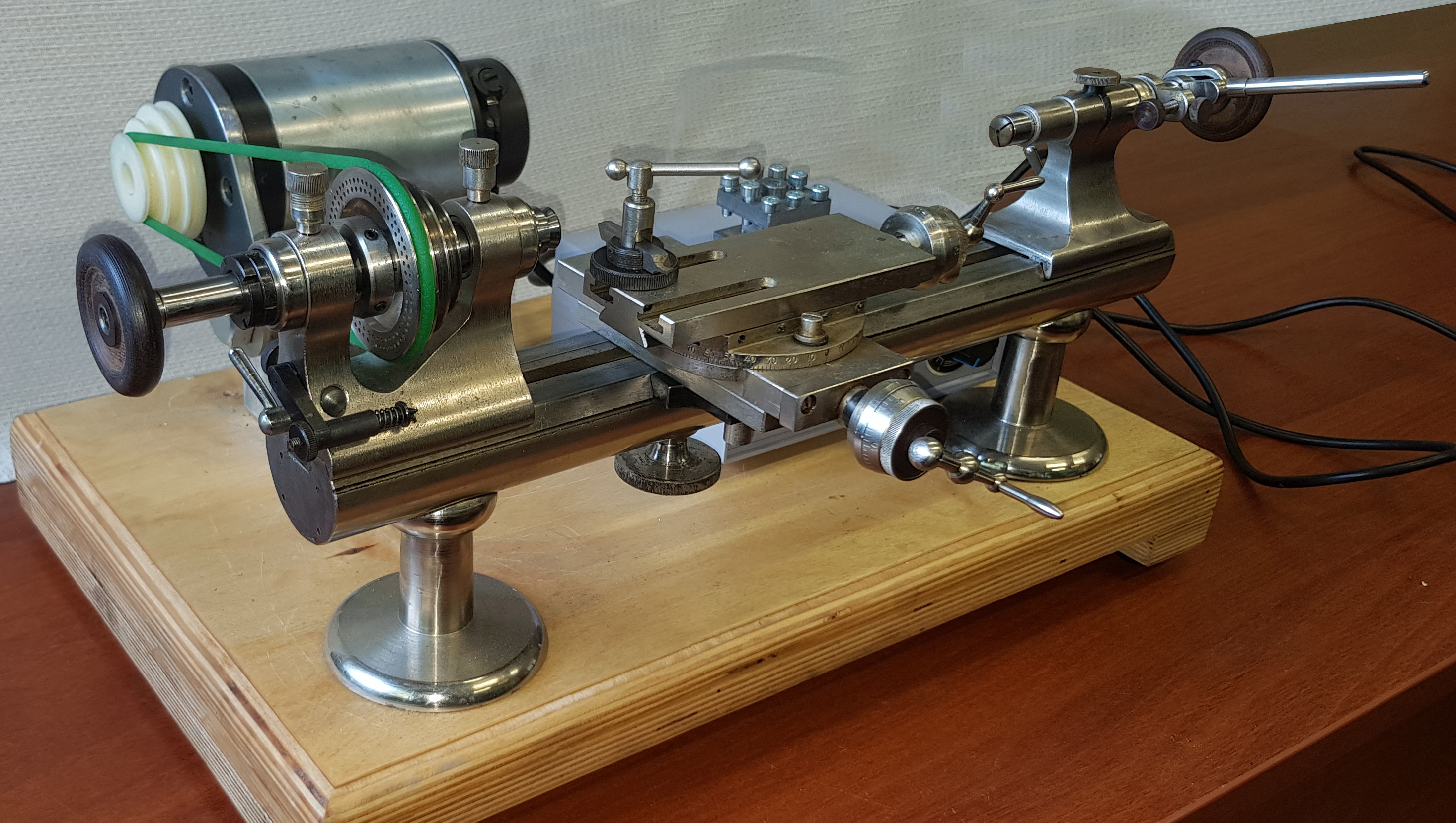

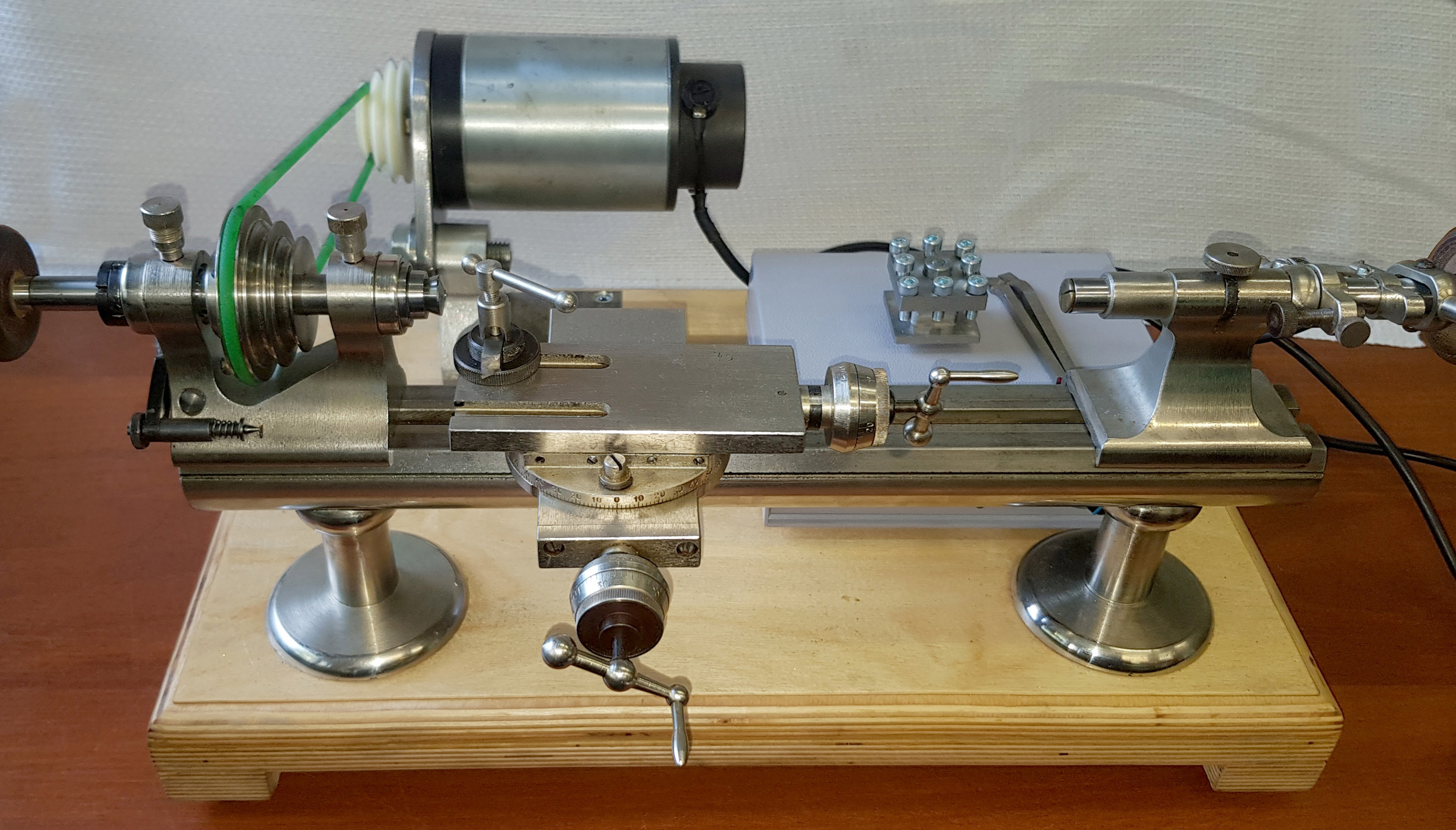

The Russian lathe operates on the same fundamental principles as other lathes, but its unique design elements contribute to its superior performance. At its core, the lathe is a machine that rotates a workpiece on its axis while a cutting tool shapes it into the desired form. This process is essential for creating cylindrical parts, threads, and other intricate designs.

The key components of a Russian lathe include the bed, headstock, tailstock, carriage, and tool post. The bed serves as the foundation, providing stability and alignment for the other components. The headstock houses the spindle, which rotates the workpiece, while the tailstock supports the opposite end. The carriage and tool post hold and guide the cutting tool, allowing for precise movements.

Step-by-Step Operation

- Secure the workpiece between the headstock and tailstock.

- Set the spindle speed and direction according to the material and desired outcome.

- Position the cutting tool using the carriage and tool post.

- Engage the spindle and allow the lathe to shape the workpiece.

- Monitor the process and make adjustments as needed.

Understanding these mechanics is crucial for operating the Russian lathe effectively and safely.

Read also:Understanding Technical Constraints A Comprehensive Guide

Types of Russian Lathes

There are several types of Russian lathes, each designed for specific applications and materials. The most common types include bench lathes, engine lathes, and turret lathes. Each type offers unique features and advantages, making them suitable for different tasks.

Bench Lathes

Bench lathes are compact and portable, making them ideal for small-scale projects and workshops. They are often used for woodworking, metalworking, and hobbyist applications.

Engine Lathes

Engine lathes are larger and more robust, designed for heavy-duty industrial use. They are commonly used in manufacturing plants and machine shops for producing large components and parts.

Turret Lathes

Turret lathes are equipped with multiple tool holders, allowing for sequential operations without the need for manual tool changes. This makes them highly efficient for mass production.

Applications in Various Industries

The Russian lathe has found applications in a wide range of industries, thanks to its versatility and precision. From automotive manufacturing to aerospace engineering, the lathe plays a crucial role in producing high-quality components and parts.

Automotive Industry

In the automotive industry, Russian lathes are used to manufacture engine components, such as pistons, crankshafts, and camshafts. Their ability to produce precise and consistent parts is essential for ensuring the performance and reliability of vehicles.

Aerospace Industry

The aerospace industry relies on Russian lathes for producing complex and lightweight components, such as turbine blades and structural parts. The precision and accuracy of the lathe are critical for meeting the stringent requirements of aerospace engineering.

Woodworking Industry

Woodworkers use Russian lathes to create intricate designs and shapes in wood, such as furniture legs, decorative items, and musical instruments. The lathe's ability to handle various materials makes it a valuable tool in this industry.

Maintenance and Safety Tips

Proper maintenance and safety practices are essential for ensuring the longevity and performance of your Russian lathe. Regular cleaning, lubrication, and inspection can prevent wear and tear, while following safety guidelines can protect you from accidents and injuries.

Maintenance Tips

- Clean the lathe after each use to remove dust and debris.

- Lubricate moving parts regularly to reduce friction and wear.

- Inspect the spindle, belts, and other components for signs of damage or wear.

Safety Tips

- Always wear protective gear, such as goggles and gloves, when operating the lathe.

- Ensure the workpiece is securely clamped before starting the machine.

- Keep loose clothing and long hair away from moving parts.

How to Choose the Right Russian Lathe

Selecting the right Russian lathe for your needs requires careful consideration of several factors. These include the type of projects you plan to undertake, the materials you'll be working with, and your budget.

Factors to Consider

- Size and capacity of the lathe.

- Type of spindle and motor power.

- Availability of accessories and tooling options.

By evaluating these factors, you can choose a Russian lathe that meets your requirements and delivers optimal performance.

Advantages of Using a Russian Lathe

The Russian lathe offers several advantages that make it a preferred choice for many industries. Its robust design, precision, and versatility are just a few of the reasons why it remains popular today.

Key Advantages

- High precision and accuracy in machining.

- Durability and reliability for long-term use.

- Versatility in handling various materials and applications.

These advantages make the Russian lathe an invaluable tool for professionals and hobbyists alike.

Modern-Day Relevance of the Russian Lathe

Despite the advancements in technology, the Russian lathe continues to hold its ground in the modern manufacturing landscape. Its ability to adapt to new materials and techniques ensures its relevance in today's industries.

Integration with CNC Technology

Many Russian lathes have been integrated with computer numerical control (CNC) technology, allowing for automated and precise operations. This integration has expanded the capabilities of the lathe, making it suitable for complex and high-volume production tasks.

Sustainability and Efficiency

The Russian lathe's efficiency in material usage and energy consumption aligns with the growing emphasis on sustainability in manufacturing. Its ability to produce high-quality parts with minimal waste makes it an eco-friendly choice.

Technical Specifications and Data

To provide a clearer understanding of the Russian lathe, here is a table summarizing its technical specifications and data.

| Specification | Details |

|---|---|

| Spindle Speed | 500-3000 RPM |

| Motor Power | 2-5 HP |

| Swing Over Bed | 10-20 inches |

| Distance Between Centers | 20-40 inches |

| Weight | 500-1000 lbs |

Conclusion and Call to Action

In conclusion, the Russian lathe is a remarkable piece of machinery with a rich history and a promising future. Its precision, durability, and versatility make it an essential tool in various industries, from automotive to aerospace. By understanding its mechanics, applications, and maintenance requirements, you can harness the full potential of the Russian lathe in your projects.

We encourage you to share your thoughts and experiences with the Russian lathe in the comments below. Have you used one before? What challenges or successes have you encountered? Additionally, feel free to share this article with fellow enthusiasts and explore other informative content on our site. Your engagement helps us continue providing valuable insights and resources for our readers.